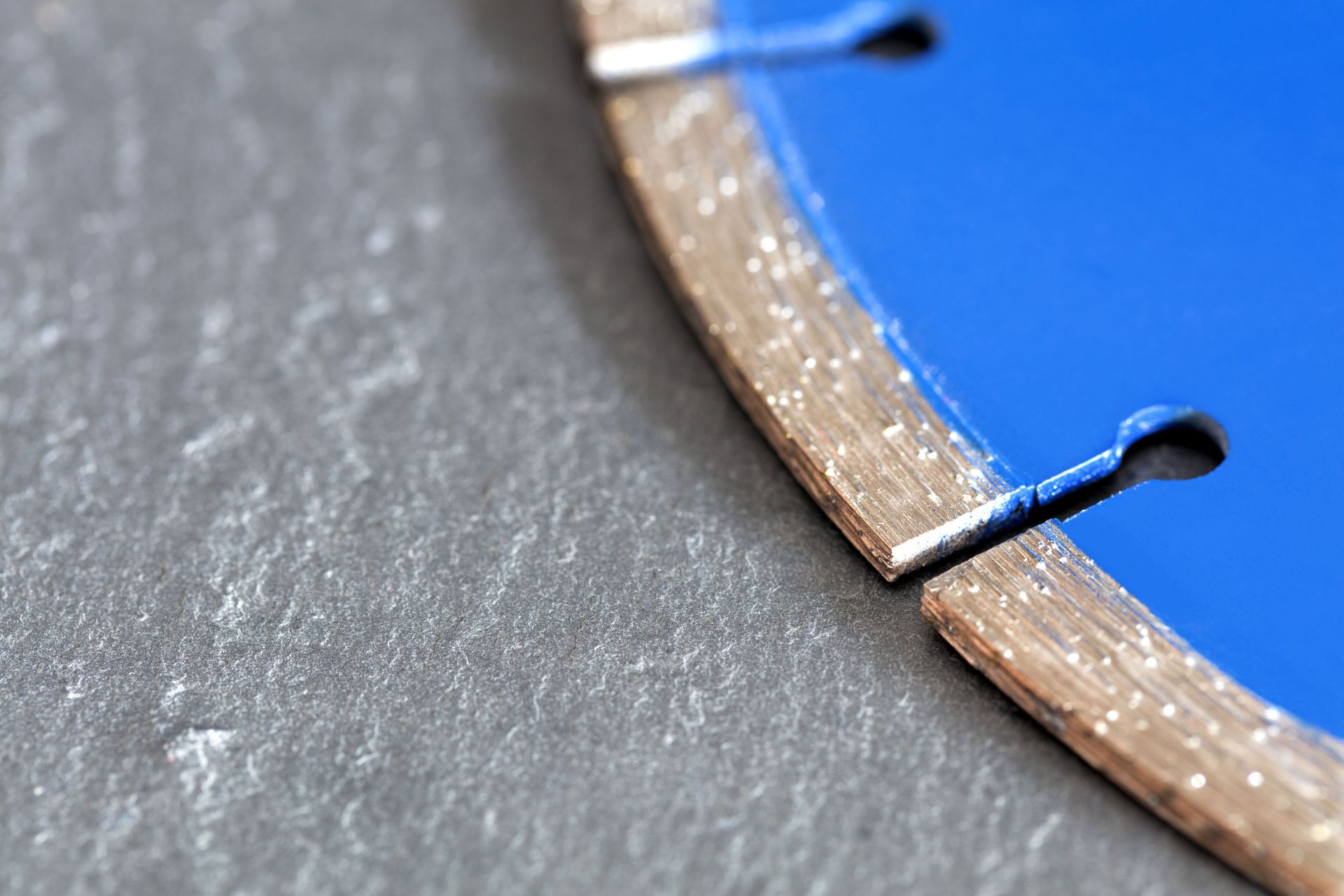

| Core or Segment Cracks | |

|---|---|

| Cause: | Blade is too hard for material being cut. |

| Solution: | Use a softer bonded blade. |

| Cause: | Blade mounted improperly; Saw in need of repair. |

| Solution: | Check it saw is in good condition and make sure blade is rated for the equipment used. Check all bearings, belts, shaft, and flanges. Check direction of blade travel. |

| Undercutting | |

|---|---|

| Cause: | Steel core wears faster than diamond segments caused by highly abrasive fines grinding against blade during cutting. |

| Solution: | Use blade with wear-retardant cores. Increase water flow to flush out cut. |

| Uneven Segment Wear | |

|---|---|

| Cause: | Insufficient water flow on one side of blade. |

| Solution: | Flush water system and check for adequate and equal water flow/distribution. |

| Cause: | Equipment defect which causes segment to wear unevenly. |

| Solution: | Replace bad bearings, worn arbor shaft, or misaligned spindle. |

| Arbor Hole Out-Of-Round | |

|---|---|

| Cause: | Blade collar not properly tightened, allowing blade to rotate or vibrate on shaft. |

| Solution: | Tighten arbor nut with wrench making sure blade is properly secured. |

| Cause: | Blade not properly mounted. |

| Solution: | Check to make sure blade is mounted on proper diameter of shaft before tightening arbor nut. Make sure pin hole slides over drive pin. |

| Wobbling / Warped Blade | |

|---|---|

| Cause: | Blade collar mounted improperly. Incorrect collar size. Blade used at improper RPM. |

| Solution: | Check RPM rating for blade and saw. Make sure equipment is operating at rated RPM. Use the correct sized blade collars. Check flanges for smoothness and tightness. |

| Cause: | Steel core is not straight as a result of dropping or twisting. |

| Solution: | Discard blade, it is unsafe to use. If practical, have manufacturer remove segment and rebraze onto new blank. |

| Segment Loss | |

|---|---|

| Cause: | Blade is too hard for material being cut. |

| Solution: | Use blade with proper specification for material being cut. |

| Cause: | Steel center is worn due to undercutting. |

| Solution: | Use sufficient water to flush out cut. |

| Short Blade Life | |

|---|---|

| Cause: | Blade is too soft for material. |

| Solution: | Choose blade with a more water-resistant bond appropriate for the application. Check water flow and make sure blade is rated for the equipment used. |

| Slow Cutting Speed | |

|---|---|

| Cause: | Material being cut is too hard for the blade. The hard material wears the exposed diamonds but not the metal portion of the segment. The segment wears too slowly, no new diamonds are exposed. |

| Solution: | Cut a soft abrasive material until diamonds are well exposed. Try asphalt block, sandstone, or dried mortar. Choose proper blade for the application. |

| Overheating | |

|---|---|

| Cause: | Inadequate coolant. |

| Solution: | Follow guidelines for proper blade operation and cooling procedures. Check water flow. Make sure blade is rated for the equipment used. |